Weso – Longer service life for your tools

Tool life optimization of tools and coatings

Tool life optimization of tools and coatings

Material optimization

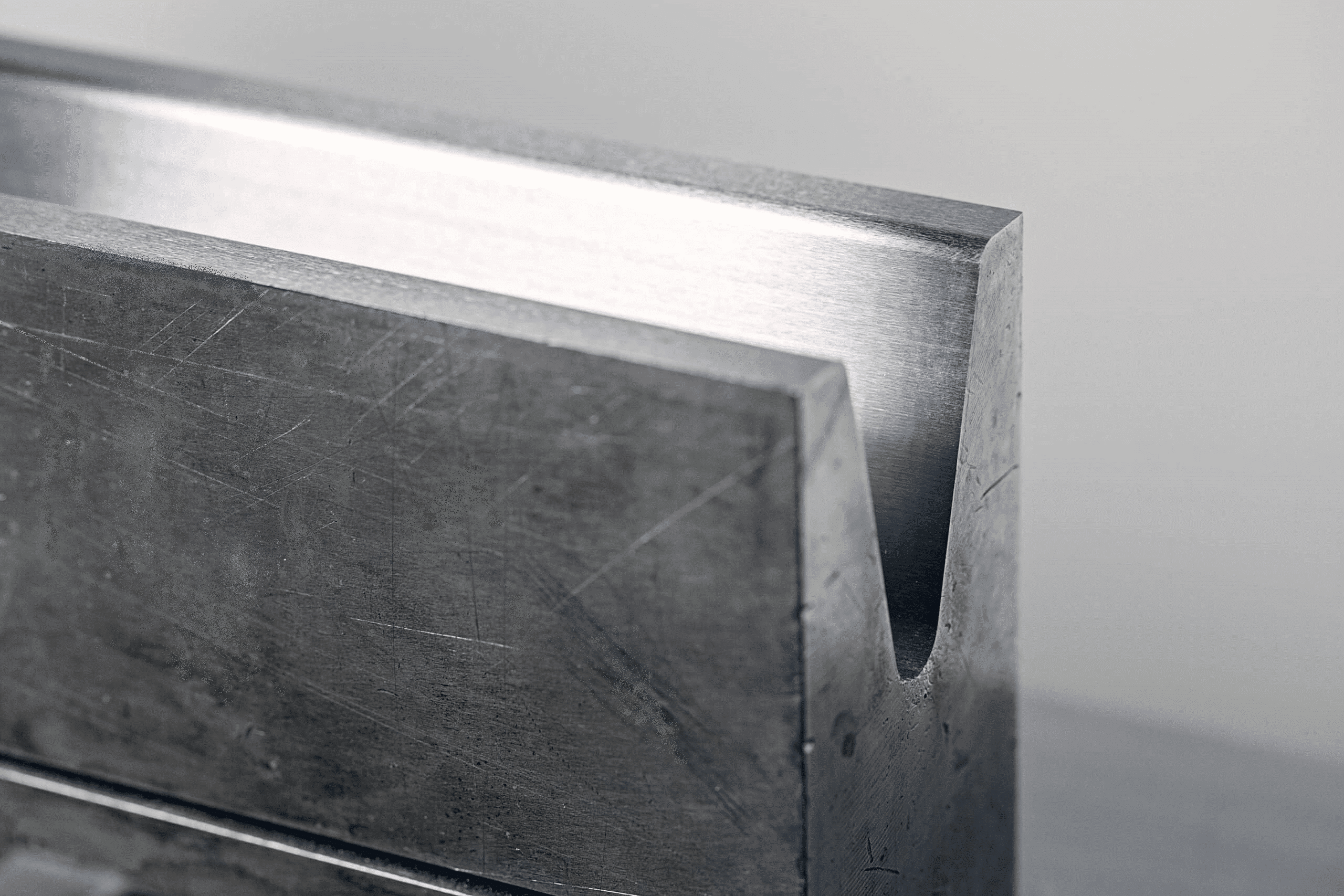

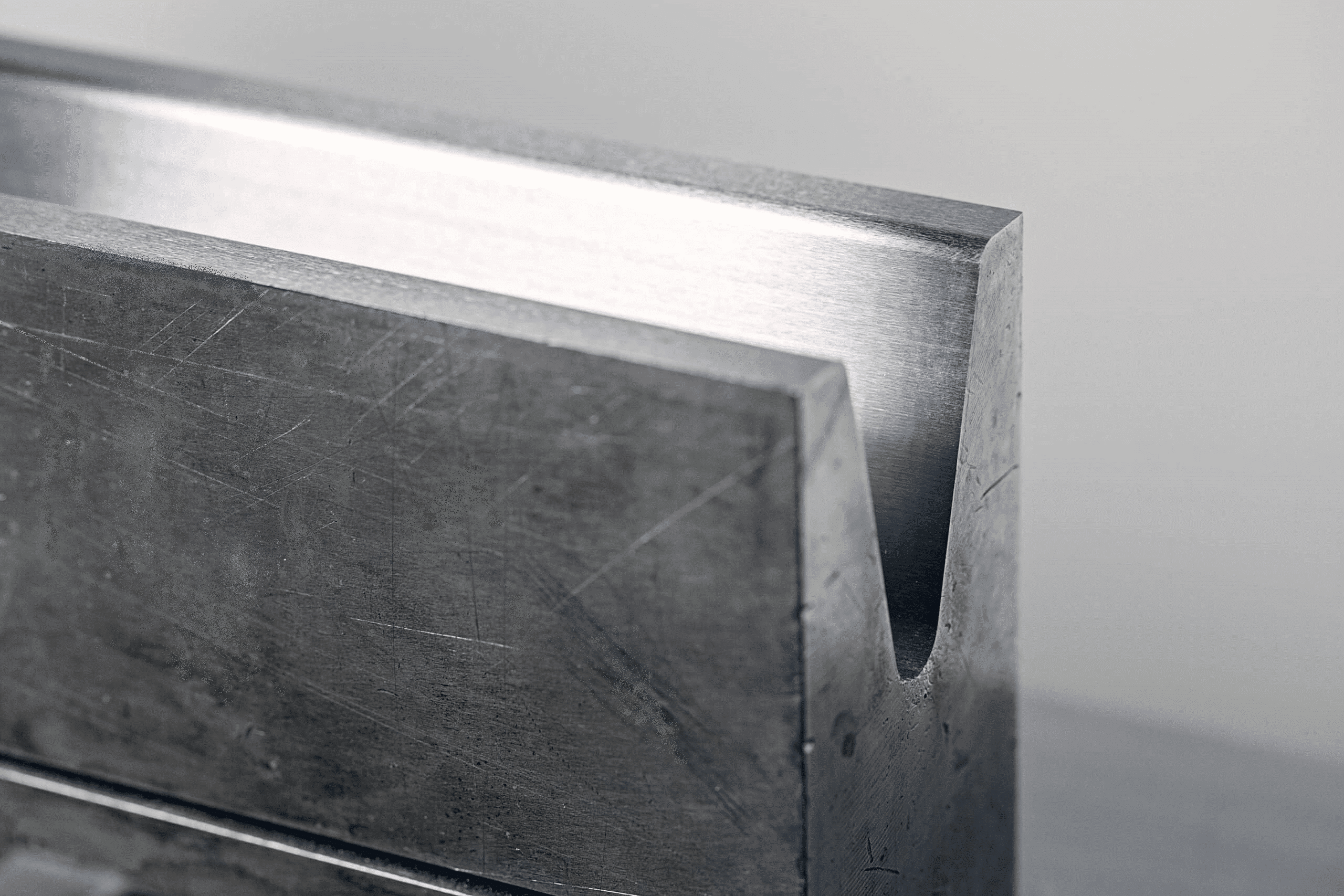

Selecting the right tool material and the right geometry is the first step towards optimizing tool life. High-performance materials such as carbides and powder metallurgical steels often offer a longer tool life compared to standard materials. The geometry of the tool also influences its wear behavior and should be tailored to the specific application.

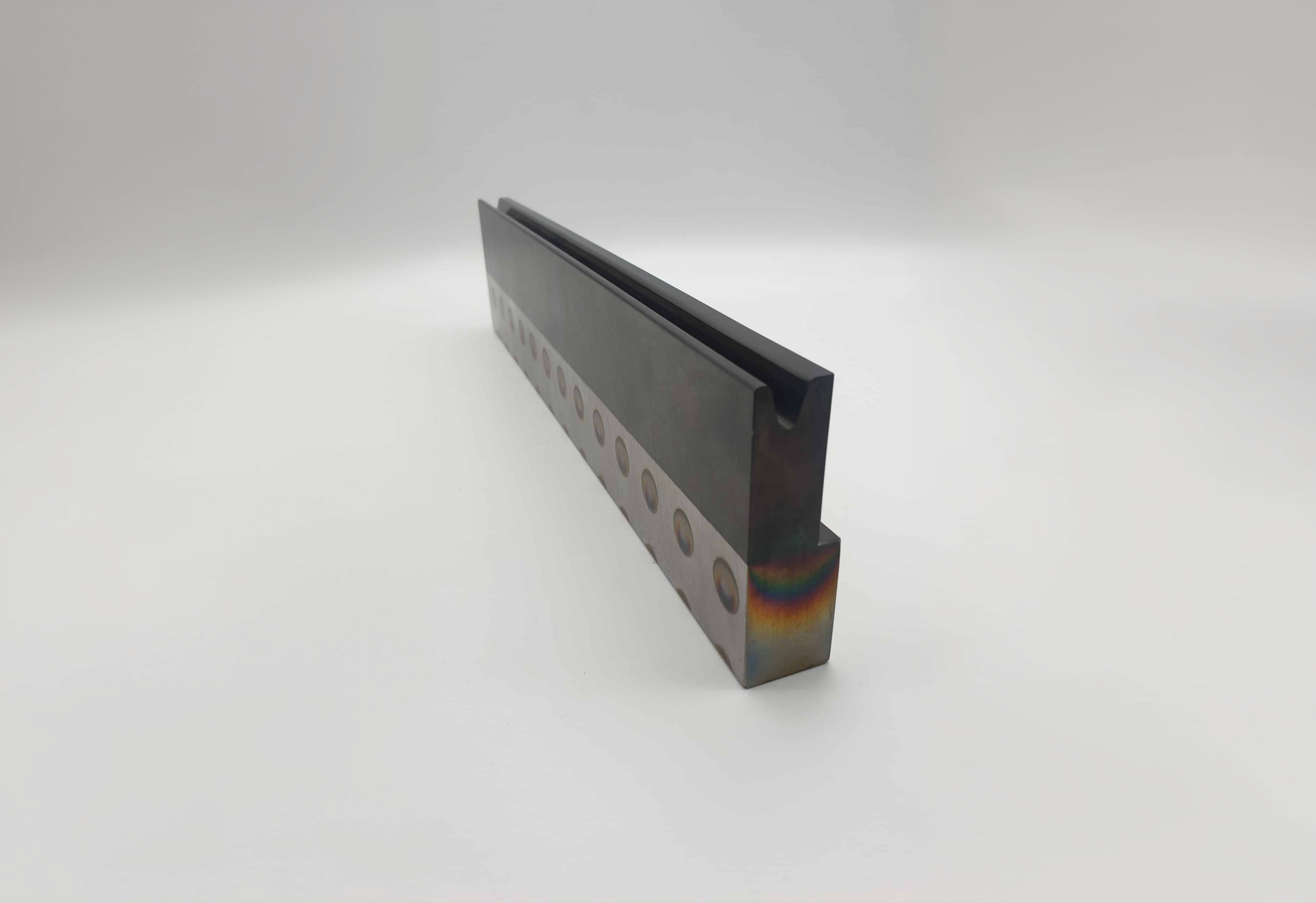

Particularly in the area of punching tools and forming tools, targeted cooling and lubrication can significantly extend the service life of a tool. Coolants reduce operating temperatures and thus prevent premature wear, while lubricants minimize friction between the tool and the workpiece.

Material optimization

Selecting the right tool material and the right geometry is the first step towards optimizing tool life.

High-performance materials such as carbides and powder metallurgical steels often offer a longer tool life compared to standard materials.

The geometry of the tool also influences its wear behavior and should be tailored to the specific application.

Particularly in the field of punching and forming tools, targeted cooling and lubrication can significantly extend the service life of a tool.

Coolants reduce operating temperatures and thus prevent premature wear, while lubricants minimize friction between the tool and the workpiece.

Coating optimization

Die Auswahl des richtigen Beschichtungsmaterials ist entscheidend für die Standzeit der Beschichtung. Beschichtungen wie PVD oder CVD sind beispielsweise besonders widerstandsfähig gegen chemische und mechanische Einflüsse.

Beschichtungsverfahren

Das Beschichtungsverfahren hat einen großen Einfluss auf die Haltbarkeit der Beschichtung. Es ist wichtig für den jeweiligen Anwendungsfall, dass richtige Verfahren und die Beschichtung zu wählen, um die optimale Standzeit zu erreichen.

Vorbehandlung der Oberflächen

Eine gründliche Vorbehandlung der zu beschichtenden Oberfläche ist entscheidend für die Haftung und Langlebigkeit der Beschichtung.

Coating optimization

Die Auswahl des richtigen Beschichtungsmaterials ist entscheidend für die Standzeit der Beschichtung. Beschichtungen wie PVD oder CVD sind beispielsweise besonders widerstandsfähig gegen chemische und mechanische Einflüsse.

Beschichtungsverfahren

Das Beschichtungsverfahren hat einen großen Einfluss auf die Haltbarkeit der Beschichtung. Es ist wichtig für den jeweiligen Anwendungsfall, dass richtige Verfahren und die Beschichtung zu wählen, um die optimale Standzeit zu erreichen.

Vorbehandlung der Oberflächen

Eine gründliche Vorbehandlung der zu beschichtenden Oberfläche ist entscheidend für die Haftung und Langlebigkeit der Beschichtung.

Summary

Optimizing the service life of tools and coatings is a complex process that requires a combination of material selection, processing technology and process monitoring.

By taking targeted measures, a company can not only significantly extend the service life of its tools, but also increase the efficiency of the entire production process.

Tool life optimization is not only a method of cutting costs by reducing tool and material wear, but also a way of increasing the quality of the end products.

Companies that invest in intelligent tool life optimization are better equipped for the highly competitive industry and can make their production processes more efficient and sustainable.

Summary

Optimizing the service life of tools and coatings is a complex process that requires a combination of material selection, processing technology and process monitoring.

By taking targeted measures, a company can not only significantly extend the service life of its tools, but also increase the efficiency of the entire production process.

Tool life optimization is not only a method of cutting costs by reducing tool and material wear, but also a way of increasing the quality of the end products.

Companies that invest in intelligent tool life optimization are better equipped for the highly competitive industry and can make their production processes more efficient and sustainable.

Ihr direkter Kontakt zu uns

Wir helfen weiter

Ihr direkter Kontakt zu uns

Wir helfen weiter

WESO WERKZEUGBAU GMBH

Address

Gewerbestr. 1-3

33818 Leopoldshöhe-Asemissen

Telephone

Fax

+49 5202 9262 39

WESO WERKZEUGBAU GMBH

Address

Gewerbestr. 1-3

33818 Leopoldshöhe-Asemissen

Telephone

Fax

+49 5202 9262 39